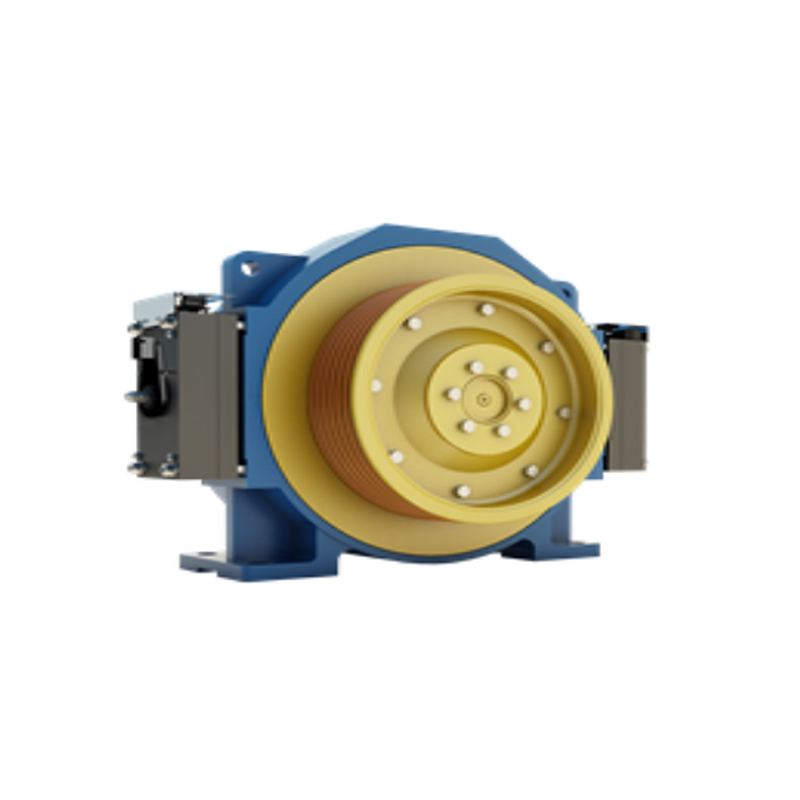

Gearless Traction Machine-AF-CK200

Model:AF-CK200

Permanent Magnet Synchronous Gearless Traction Machine

Voltage:380V

Elv.Load:630-1150Kg Elv.Speed:0.5-2.5m/s

Sheave Diam:400mm/450mm

Brake:DC110V 2×1.3A

IP proof: IP41

Ins.Classs:F

Roping:2:1/4:1

Duty:S5-40%

Max.Static Load:4000kg

Weight:350Kg

| Spec | Elv Load (kg) | Elv Speed (m/s) | Sheave Dia (mm) | Sheave Groove | Currect(A) | Power(KW) | Speed(r/min) | Freq(Hz) | Torque(N.m) | Poles | L (mm) | L1 (mm) | β Angle(。) |

| Roping:2:1 | |||||||||||||

| 630-0.5 | 630 | 0.5 | 400 | 4×Φ10×15 | 6 | 2.2 | 48 | 12.8 | 430 | 32 | 288 | 69.5 | 95 |

| 630-0.63 | 630 | 0.63 | 400 | 4×Φ10×15 | 6 | 2.7 | 60 | 16.0 | 430 | 32 | 288 | 69.5 | |

| 630-1.0 | 630 | 1.0 | 400 | 4×Φ10×15 | 10 | 4.3 | 95 | 25.3 | 430 | 32 | 288 | 69.5 | |

| 630-1.5 | 630 | 1.5 | 400 | 4×Φ10×15 | 14 | 6.4 | 143 | 38.1 | 430 | 32 | 288 | 69.5 | |

| 630-1.6 | 630 | 1.6 | 400 | 4×Φ10×15 | 16 | 6.9 | 153 | 40.8 | 430 | 32 | 288 | 69.5 | |

| 630-1.75 | 630 | 1.75 | 400 | 4×Φ10×15 | 16 | 7.5 | 167 | 44.5 | 430 | 32 | 288 | 69.5 | |

| 630-2.0A | 630 | 2.0 | 400 | 4×Φ10×15 | 18 | 8.6 | 191 | 50.9 | 430 | 32 | 288 | 69.5 | |

| 630-2.0B | 630 | 2.0 | 400 | 4×Φ10×15 | 18 | 8.5 | 170 | 45.3 | 480 | 32 | 288 | 69.5 | |

| 800-0.5 | 800 | 0.5 | 400 | 5×Φ10×15 | 8 | 2.7 | 48 | 12.8 | 540 | 32 | 288 | 69.5 | |

| 800-0.63 | 800 | 0.63 | 400 | 5×Φ10×15 | 8 | 3.4 | 60 | 16.0 | 540 | 32 | 288 | 69.5 | |

| 800-1.0 | 800 | 1.0 | 400 | 5×Φ10×15 | 12 | 5.4 | 95 | 25.3 | 540 | 32 | 288 | 69.5 | |

| 800-1.5 | 800 | 1.5 | 400 | 5×Φ10×15 | 18 | 8.1 | 143 | 38.1 | 540 | 32 | 288 | 69.5 | |

| 800-1.6 | 800 | 1.6 | 400 | 5×Φ10×15 | 20 | 8.7 | 153 | 40.8 | 540 | 32 | 288 | 69.5 | |

| 800-1.75 | 800 | 1.75 | 400 | 5×Φ10×15 | 20 | 9.4 | 167 | 44.5 | 540 | 32 | 288 | 69.5 | |

| 800-2.0A | 800 | 2.0 | 400 | 5×Φ10×15 | 23 | 10.8 | 191 | 50.9 | 540 | 32 | 288 | 69.5 | |

| 800-2.0B | 800 | 2.0 | 450 | 5×Φ10×15 | 23 | 10.7 | 170 | 45.3 | 600 | 32 | 288 | 69.5 | |

| 800-2.5A | 800 | 2.5 | 400 | 6×Φ10×15 | 28 | 13.5 | 239 | 63.7 | 540 | 32 | 300 | 75.5 | |

| 800-2.5B | 800 | 2.5 | 450 | 5×Φ10×15 | 29 | 13.3 | 212 | 56.5 | 600 | 32 | 288 | 69.5 | |

| 1000-0.5 | 1000 | 0.5 | 400 | 5×Φ10×15 | 10 | 3.4 | 48 | 12.8 | 670 | 32 | 288 | 69.5 | |

| 1000-0.63 | 1000 | 0.63 | 400 | 5×Φ10×15 | 10 | 4.2 | 60 | 16.0 | 670 | 32 | 288 | 69.5 | |

| 1000-1.0 | 1000 | 1.0 | 400 | 5×Φ10×15 | 15 | 6.7 | 95 | 25.3 | 670 | 32 | 288 | 69.5 | |

| 1000-1.5 | 1000 | 1.5 | 400 | 5×Φ10×15 | 23 | 10.0 | 143 | 38.1 | 670 | 32 | 288 | 69.5 | |

| 1000-1.6 | 1000 | 1.6 | 400 | 5×Φ10×15 | 26 | 10.7 | 153 | 40.8 | 670 | 32 | 288 | 69.5 | |

| 1000-1.75 | 1000 | 1.75 | 400 | 5×Φ10×15 | 26 | 11.7 | 167 | 44.5 | 670 | 32 | 288 | 69.5 | |

| 1000-2.0A | 1000 | 2.0 | 400 | 5×Φ10×15 | 28 | 13.4 | 191 | 50.9 | 670 | 32 | 288 | 69.5 | |

| 1000-2.0B | 1000 | 2.0 | 450 | 5×Φ10×15 | 28 | 13.4 | 170 | 45.3 | 750 | 32 | 288 | 69.5 | |

| 1000-2.5A | 1000 | 2.5 | 400 | 6×Φ10×15 | 34 | 16.8 | 239 | 63.7 | 670 | 32 | 300 | 75.5 | |

| 1000-2.5B | 1000 | 2.5 | 450 | 6×Φ10×15 | 36 | 16.6 | 212 | 56.5 | 750 | 32 | 300 | 75.5 | |

| 1150-0.5 | 1150 | 0.5 | 400 | 5×Φ10×15 | 12 | 3.9 | 48 | 12.8 | 780 | 32 | 288 | 69.5 | |

| 1150-0.63 | 1150 | 0.63 | 400 | 5×Φ10×15 | 12 | 4.9 | 60 | 16.0 | 780 | 32 | 288 | 69.5 | |

| 1150-1.0 | 1150 | 1.0 | 400 | 5×Φ10×15 | 17 | 7.8 | 95 | 25.3 | 780 | 32 | 288 | 69.5 | |

| 1150-1.5 | 1150 | 1.5 | 400 | 6×Φ10×15 | 29 | 11.7 | 143 | 38.1 | 780 | 32 | 300 | 75.5 | |

| 1150-1.6 | 1150 | 1.6 | 400 | 6×Φ10×15 | 29 | 12.5 | 153 | 40.8 | 780 | 32 | 300 | 75.5 | |

| 1150-1.75 | 1150 | 1.75 | 400 | 6×Φ10×15 | 29 | 13.6 | 167 | 44.5 | 780 | 32 | 300 | 75.5 | |

| 1150-2.0 | 1150 | 2.0 | 400 | 6×Φ10×15 | 33 | 15.6 | 191 | 50.9 | 780 | 32 | 300 | 75.5 | |

| Roping:4:1 | |||||||||||||

| 2000-1.0 | 2000 | 1.0 | 400 | 5×Φ8×12 | 15 | 6.7 | 95 | 25.3 | 670 | 32 | 288 | 69.5 | According to working conditions |

| 2000-1.5 | 2000 | 1.5 | 400 | 6×Φ8×12 | 28 | 13.4 | 191 | 50.9 | 670 | 32 | 288 | 69.5 | |

Remark: 1.the machine can be used for machine roomless.

2.The above is recommended value of cut angle.it's optional according to practical condition.