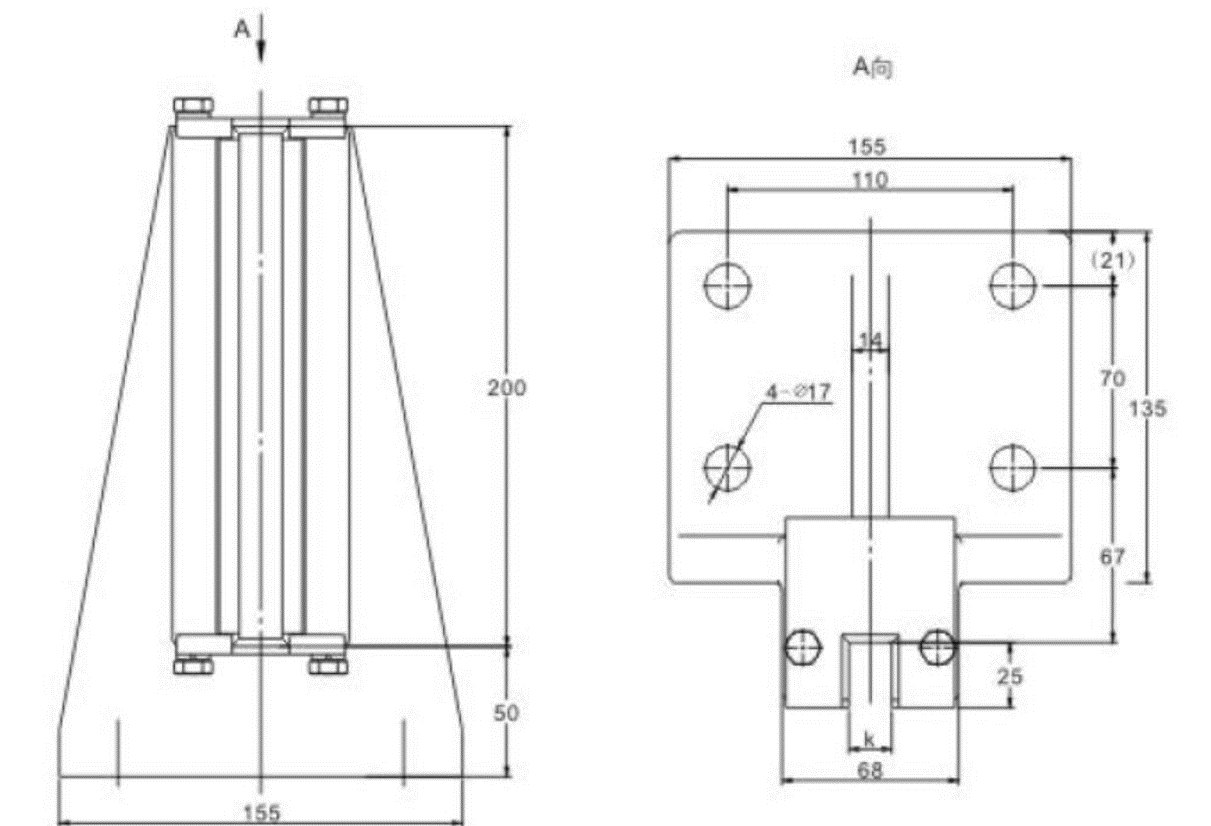

Guide Shoes-AF-H16

1.The rolling guide shoe is stuck on the track with 3 or 6 wheels, and is generally used for elevators with a speed of more than 2 meters!

Features: Sliding friction is replaced by rolling friction, which reduces friction loss, reduces vibration and noise during operation, and improves ride comfort, but the processing and installation requirements of this guide shoe are relatively high.

2.The fixed sliding guide shoe is a chute stuck on the guide rail. "It is the concave groove", which is generally used for elevators with a speed of less than 2 meters!

Features: Because the guide shoe head is fixed, the structure is simple, and there is no adjustment mechanism, as the running time of the elevator increases, the matching gap between the guide shoe and the guide rail will become larger and larger, and the car will shake during operation, even There is an impact.

3. Elastic sliding guide shoes are further divided into spring sliding guide shoes (suitable for elevators with rated speed less than 1.7M/S) and rubber spring sliding guide shoes (suitable for medium and high-speed elevators).

Mode:AF-H16

Rated Speed: ≤1.75m/s

Match the Guide rail: 10;16

Applicable to the lateral capsules